Page 137 - Demo

P. 137

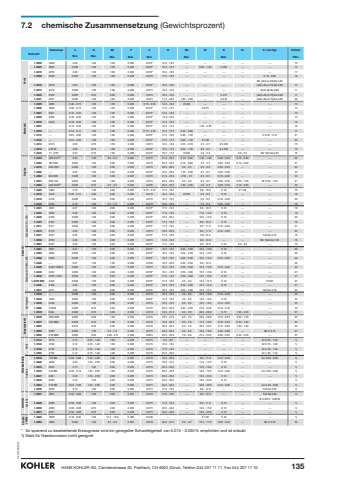

© KOHLER 2023HANS KOHLER AG, Claridenstrasse 20, Postfach, CH-8022 Zürich, Telefon 044 207 11 11, Fax 044 207 11 10 1357.2 chemische Zusammensetzung (Gewichtsprozent)WerkstoffOutokumpu C Si Mn P S Cr Mo Ni N Cu Ti / sonstige mittlererMax. Max. Max. Max. Max. Max. Max. PRE16Ferrit1.4000 4000 0.08 1.00 1.00 0.040 0.015* 12.0 - 14.0 --- --- --- --- --- 131.4003 4003 0.030 1.00 1.50 0.040 0.015* 10.5 - 12.5 --- 0.30 - 1.00 0.030 --- --- 121.4016 4016 0.08 1.00 1.00 0.040 0.015* 16.0 - 18.0 --- --- --- --- --- 171.4509 4509 0.030 1.00 1.00 0.040 0.015 17.5 - 18.5 --- --- --- --- 0.10 - 0.60 18Nb: [3xC+0.30] bis 1.001.4510 4510 0.05 1.00 1.00 0.040 0.015* 16.0 - 18.0 --- --- --- --- [4x(C+N)+0.15] bis 0.80 171.4512 4512 0.030 1.00 1.00 0.040 0.015 10.5 - 12.5 --- --- --- --- 6x(C+N) bis 0.65 111.4520 4520 0.025 0.50 0.50 0.040 0.015 16.0 - 18.0 --- --- 0.015 --- [4x(C+N)+0.15] bis 0.80 171.4521 4521 0.025 1.00 1.00 0.040 0.015 17.0 - 20.0 1.80 - 2.50 --- 0.030 --- [4x(C+N)+0.15] bis 0.80 26Martensit1.4005 4005 0.06 - 0.15 1.00 1.50 0.040 0.15 - 0.35 12.0 - 14.0 # 0.60 --- --- --- --- 131.4006 4006 0.08 - 0.15 1.00 1.50 0.040 0.015* 11.5 - 13.5 --- # 0.75 --- --- --- 131.4021 4021 0.16 - 0.25 1.00 1.50 0.040 0.015* 12.0 - 14.0 --- --- --- --- --- 131.4028 4028 0.26 - 0.35 1.00 1.50 0.040 0.015* 12.0 -14.0 --- --- --- --- --- 131.4034 4034 0.43 - 0.50 1.00 1.00 0.040 0.015* 12.5 - 14.5 --- --- --- --- --- 141.4057 --- 0.12 - 0.22 1.00 1.50 0.040 0.015* 15.0 - 17.0 --- 1.50 - 2.50 --- --- --- 161.4104 --- 0.10 - 0.17 1.00 1.50 0.040 0.15 - 0.35 15.5 - 17.5 0.20 - 0.60 --- --- --- - 171.4112 --- 0.85 - 0.95 1.00 1.00 0.040 0.015* 17.0 - 19.0 0.90 - 1.30 --- --- --- V: 0.07 - 0.12 211.4122 --- 0.33 - 0.45 1.00 1.50 0.040 0.015* 15.5 - 17.5 0.80 - 1.30 # 1.00 --- --- --- 201.4313 4313 0.05 0.70 1.50 0.040 0.015 12.0 - 14.0 0.30 - 0.70 3.5 - 4.5 # 0.020 --- --- 151.4418 248 SV 0.06 0.70 1.50 0.040 0.015* 15.0 - 17.0 0.80 - 1.50 4.0 - 6.0 # 0.020 --- --- 191.4542 17- 4 PH 0.07 0.70 1.50 0.040 0.015* 15.0 - 17.0 # 0.60 3.0 - 5.0 --- 3.0 - 5.0 Nb: 5xC bis 0.45 16Duplex1.4162 LDX 2101® 0.04 1.00 4.0 - 6.0 0.040 0.015 21.0 - 22.0 0.10 - 0.80 1.35 - 1.90 0.20 - 0.25 0.10 - 0.80 --- 261.4362 DX 2304 0.030 1.00 2.00 0.035 0.015 22.0 - 24.5 0.10 - 0.60 3.5 - 5.5 0.05 - 0.20 0.10 - 0.60 --- 271.4410 SDX 2507 0.030 1.00 2.00 0.035 0.015 24.0 - 26.0 3.0 - 4.5 6.0 - 8.0 0.24 - 0.35 --- --- 421.4460 --- 0.05 1.00 2.00 0.035 0.015* 25.0 - 28.0 1.30 - 2.00 4.5 - 6.5 0.05 - 0.20 --- --- 341.4462 DX 2205 0.030 1.00 2.00 0.035 0.015 21.0 - 23.0 2.50 - 3.5 4.5 - 6.5 0.10 - 0.22 --- --- 341.4501 SDX 100 0.030 1.00 1.00 0.035 0.015 24.0 - 26.0 3.0 - 4.0 6.0 - 8.0 0.20 - 0.30 0.50 - 1.00 W: 0.50 - 1.00 411.4662 LDX 2404® 0.030 0.70 2.5 - 4.0 0.035 0.005 23.0 - 25.0 1.00 - 2.00 3.0 - 4.5 0.20 - 0.30 0.10 - 0.80 --- 34Austenit1.4305 4305 0.10 1.00 2.00 0.045 0.15 - 0.35 17.0 - 19.0 - 8.0 - 10.0 0.10 # 1.00 --- 181.4310 4310 0.05 - 0.15 2.00 2.00 0.045 0.015 16.0 - 19.0 # 0.80 6.0 - 9.5 0.10 --- --- 181.4318 4318 0.030 1.00 2.00 0.045 0.015 16.5 - 18.5 --- 6.0 - 8.0 0.10 - 0.20 --- --- 201.4372 4372 0.15 1.00 5.5 - 7.5 0.045 0.015 16.0 - 18.0 --- 3.5 - 5.5 0.05 - 0.25 --- --- 19Standard Cr-Ni / V2A1.4301 4301 0.07 1.00 2.00 0.045 0.015* 17.5 - 19.5 --- 8.0 - 10.5 0.10 --- --- 191.4303 4303 0.06 1.00 2.00 0.045 0.015* 17.0 - 19.0 --- 11.0 - 13.0 0.10 --- --- 191.4306 4306 0.030 1.00 2.00 0.045 0.015* 18.0 - 20.0 --- 10.0 - 12.0 0.10 --- --- 201.4307 4307 0.030 1.00 2.00 0.045 0.015* 17.5 - 19.5 --- 8.0 - 10.5 0.10 --- --- 191.4311 4311 0.030 1.00 2.00 0.045 0.015* 17.5 - 19.5 --- 8.5 - 11.5 0.12 - 0.22 --- --- 211.4315 4315 0.06 1.00 2.00 0.045 0.015 18.0 - 20.0 --- 8.0 - 11.0 0.12 - 0.22 --- --- 221.4541 4541 0.08 1.00 2.00 0.045 0.015* 17.0 - 19.0 --- 9.0 -12.0 --- --- 5xC bis 0.70 181.4550 4550 0.08 1.00 2.00 0.045 0.015 17.0 - 19.0 --- 9.0 - 12.0 --- --- Nb: 10xC bis 1.00 181.4567 4567 0.04 1.00 2.00 0.045 0.015* 17.0 - 19.0 --- 8.5 - 10.5 0.10 3.0 - 4.0 ---- 19Standard Cr-Ni-Mo / V4A1.4401 4401 0.07 1.00 2.00 0.045 0.015* 16.5 - 18.5 2.00 - 2.50 10.0 - 13.0 0.10 --- --- 261.4404 4404 0.030 1.00 2.00 0.045 0.015* 16.5 - 18.5 2.00 - 2.50 10.0 - 13.0 0.10 --- --- 261.4406 4406 0.030 1.00 2.00 0.045 0.015* 16.5 - 18.5 2.00 - 2.50 10.0 - 12.5 0.12 - 0.22 --- --- 281.4408 --- 0.07 1.50 1.50 0.040 0.030 18.0 - 20.0 2.00 - 2.50 9.0 - 12.0 - --- --- 261.4429 4429 / SKR-4 0.030 1.00 2.00 0.045 0.015 16.5 - 18.5 2.50 - 3.00 10.5 - 14.0 0.12 - 0.22 --- --- 291.4432 4432 0.030 1.00 2.00 0.045 0.015* 16.5 - 18.5 2.50 - 3.00 10.5 - 13.0 0.10 --- --- 271.4435 4435 / 724L 0.030 1.00 2.00 0.045 0.015* 17.0 - 19.0 2.50 - 3.00 12.5 - 15.0 0.10 --- --- 271.4435 BN2 4435 0.030 1.00 2.00 0.045 0.015* 17.0 - 19.0 2.5 - 3.0 12.5 - 15.0 0.10 --- # 0.05 271.4436 4436 0.05 1.00 2.00 0.045 0.015* 16.5 - 18.5 2.50 - 3.00 10.5 - 13.0 0.10 --- --- 271.4571 4571 0.08 1.00 2.00 0.045 0.015* 16.5 - 18.5 2.00 - 2.50 10.5 - 13.5 --- --- 5xC bis 0.70 25hochlegiert1.4434 --- 0.030 1.00 2.00 0.045 0.015 16.5 - 19.5 3.0 - 4.0 10.5 - 14.0 0.10 - 0.20 --- --- 321.4438 4438 0.030 1.00 2.00 0.045 0.015* 17.5 - 19.5 3.0 - 4.0 13.0 - 16.0 0.10 --- --- 321.4439 4439 0.030 1.00 2.00 0.045 0.015 16.5 - 18.5 4.0 - 5.0 12.5 - 14.5 0.12 - 0.22 --- --- 351.4466 725LN 0.020 0.70 2.00 0.025 0.010 24.0 - 26.0 2.00 - 2.50 21.0 - 23.0 0.10 - 0.16 --- --- 341.4539 904L 0.020 0.70 2.00 0.030 0.010 19.0 - 21.0 4.0 - 5.0 24.0 - 26.0 0.15 1.20 - 2.00 --- 37Superaustenit1.4529 Ultra 6XN 0.020 0.50 1.00 0.030 0.010 19.0 - 21.0 6.0 - 7.0 24.0 - 26.0 0.15 - 0.25 0.50 - 1.50 --- 451.4547 254 SMO 0.020 0.70 1.00 0.030 0.010 19.5 - 20.5 6.0 - 7.0 17.5 - 18.5 0.18 - 0.25 0.50 - 1.00 --- 451.4562 --- 0.015 0.30 2.00 0.020 0.010 26.0 - 28.0 6.0 - 7.0 30.0 - 32.0 0.15 - 0.25 1.00 - 1.40 --- 521.4565 4565 0.030 1.00 5.0 - 7.0 0.030 0.015 24.0 - 26.0 4.0 - 5.0 16.0 - 19.0 0.30 - 0.60 --- Nb: # 0.15 471.4652 654 SMO 0.020 0.50 2.00 - 4.0 0.030 0.005 23.0 - 25.0 7.0 - 8.0 21.0 - 23.0 0.45 - 0.55 0.30 - 0.60 --- 57hitzebeständigFerrit1.4713 4713 0.12 0.50 - 1.00 1.00 0.040 0.015 6.0 - 8.0 --- --- --- --- Al: 0.50 - 1.00 1)1.4724 4724 0.12 0.70 - 1.40 1.00 0.040 0.015 12.0 - 14.0 --- --- --- --- Al: 0.70 - 1.20 1)1.4742 4742 0.12 0.70 - 1.40 1.00 0.040 0.015 17.0 - 19.0 --- --- --- --- Al: 0.70 - 1.20 1)1.4762 4762 0.12 0.70 - 1.40 1.00 0.040 0.015 23.0 - 26.0 --- --- --- --- Al: 1.20 - 1.70 1)Austenit1.4818 153 MA 0.04 - 0.08 1.00 - 2.00 1.00 0.045 0.015 18.0 - 20.0 --- 9.0 - 11.0 0.12 - 0.20 --- Ce: 0.03 - 0.08 1)1.4828 4828 0.20 1.50 - 2.50 2.00 0.045 0.015 19.0 - 21.0 --- 11.0 - 13.0 0.10 --- --- 1)1.4833 4833 0.15 1.00 2.00 0.045 0.015 22.0 - 24.0 --- 12.0 - 14.0 0.10 --- --- 1)1.4835 253 MA 0.05 - 0.12 1.40 - 2.50 1.00 0.045 0.015 20.0 - 22.0 --- 10.0 - 12.0 0.12 - 0.20 --- Ce: 0.03 - 0.08 1)1.4841 4841 0.20 1.50 - 2.50 2.00 0.045 0.015 24.0 - 26.0 --- 19.0 - 22.0 0.10 --- --- 1)1.4845 4845 0.10 1.50 2.00 0.045 0.015 24.0 - 26.0 --- 19.0 - 22.0 0.10 --- --- 1)1.4854 353 MA 0.04 - 0.08 1.20 - 2.00 2.00 0.040 0.015 24.0 - 26.0 --- 34.0 - 36.0 0.12 - 0.20 --- Ce: 0.03 - 0.08 1)1.4878 4878 0.10 1.00 2.00 0.045 0.015 17.0 - 19.0 --- 9.0 - 12.0 --- --- 5xC bis 0.80 1)warmfest Austenit1.4941 4941 0.04 - 0.08 1.00 2.00 0.035 0.015 17.0 - 19.0 --- 9.0 - 12.0 --- --- 5xC bis 0.80 1)B: 0.0015 - 0.00501.4948 4948 0.04 - 0.08 1.00 2.00 0.035 0.015 17.0 - 19.0 --- 8.0 - 11.0 0.10 --- --- 1)1.4950 4950 0.04 - 0.08 0.70 2.00 0.035 0.015 22.0 - 24.0 --- 12.0 - 15.0 0.10 --- --- 1)1.4951 4951 0.04 - 0.08 0.70 2.00 0.035 0.015 24.0 - 26.0 --- 19.0 - 22.0 0.10 --- --- 1)Sonder- stähle1.3805 3805 0.30 - 0.40 1.00 17.0 - 19.0 0.060 0.030 --- --- # 1.00 0.10 --- --- 1)1.3964 3964 0.030 1.00 4.0 - 6.0 0.025 0.010 20.0 - 21.5 3.0 - 3.5 15.0 - 17.0 0.20 - 0.35 --- Nb: # 0.25 36* für spanend zu bearbeitende Erzeugnisse wird ein geregelter Schwefelgehalt von 0.015 - 0.030% empfohlen und ist erlaubt1) Stahl für Nasskorrosion nicht geeignet---